A recent trend in the industry is the move towards “smart metering”. Traditional metering types such as orifice plates and flow nozzles are being replaced and upgraded to more advanced flow meters. Vortex and ultrasonic meters are becoming more attractive to owners and operators and often offer many benefits to users. One of the most attractive benefits of both vortex and ultrasonic meters is the wide range of flows (turn-down ratios) that can be measured.

Orifice Plate http://www2.emersonprocess.com/

Orifice plates are one of the most widely used devices for flow measurement. An orifice plate is thin and concentric and is typically made out of stainless steel. When inserted into a line, a pressure drop is created from the restriction and the differential pressure is measured. Flow can be determined using well recognized formulas and empirically derived coefficients to convert the differential pressure into a flow rate. Orifice plates are inexpensive and have proven to be effective and reliable. They are easy to install, have no moving parts and can be used in both liquid and gas services. Orifice plates are limited to a turn-down ratio of 4:1.

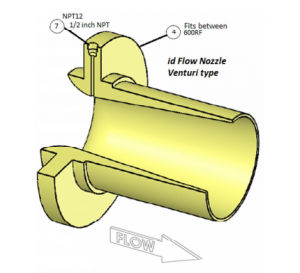

Flow nozzles have a smooth elliptical inlet leading to a throat section with a sharp outlet. A restriction is created in the flow and a pressure drop is created. A flow rate can be calculated using recognized formulas and applying Bernoulli’s equation.

Flow Nozzle ftp://ftp.idsolutions-acp.com

Flow nozzles are also inexpensive and can handle high flow rates because the smooth inlet of the nozzle results in a higher coefficient of discharge. There are no moving parts and are ideal for slurries because the nozzle provides a better path for debris. Similar to an orifice plate, flow nozzles have a turndown ratio of 4:1.

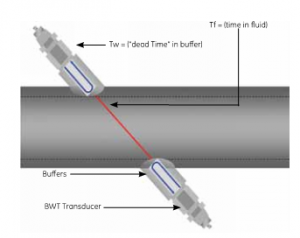

Vortex meters are constructed on the Karman vortex theory. A vortex meter contains a shedder bar, when fluid passes the shedder bar, vortices are created. The frequency that these vortices alternate the sides of the meter is proportional to the fluid flow rate. A sensor in the meter body generates an electrical pulse every time a vortex is created. The frequency of the electrical pulse is proportional to the fluid velocity and a volumetric flow rate can be calculated. Vortex meters are simple in construction and have no moving parts and are applicable in wide measurement ranges. They provide good accuracy and can be used in gas, liquid and steam measurement. There are two main types of ultrasonic flow meter technologies, transit time and Doppler. Transit time meters have both a sender and a receiver. These meters will typically have 2 or 4 transducers. These transducers will send an ultrasonic signal at an angle from one side of the pipe, to the other side, and back again. The transit time is measured and the difference of the two times is proportional to the flow rate.

Ultrasonic http://www.ge-mcs.com/en/flow/ultrasonic-liquid/panaflow-ht.html

The Doppler type meters will send a signal from the transducers but the signal will bounces off particles in the flow stream instead of the other side of the pipe. The flow particles will be travelling at the same speed as the flow. The frequency is measured when a reflected signal is detected and flow can be calculated. Ultrasonic meters have no moving parts and are typically have low maintenance. They offer a wide range of turn-down and can be used in a wide range of services.

Traditional meter types and new advanced technologies both have many advantages and disadvantages. Depending on the application and the desired accuracy, any of these meters can be used. Vortex and ultrasonic meters offer higher turndown ratios, improve accuracy and have long term reliability. The initial cost of a vortex or an ultrasonic can be expensive at first; however the lifetime cost of ownership can often justify the initial upfront costs.

Thanks